cameron.luo@zolytechmachinery.com

+86-18688657355

◆ Exclusive innovation: Adding sealing edge function, non shuttle working.

◆ No flanging machine and extra labors: quilted fabric with 4 sides locked.

◆ High quality DURKOPP Adler sewing head, imported extra size rotary shuttle.

◆ Non-contacting thread breakage detecting technology.

◆ No long-arm quilt repair machine thanks to the automatic quilt mending function.

◆ Automatic lubrication of the hook and needle system.

◆ Automatic material tension on both clamp sides.

◆ Professional industrial computer system: 100 trillion stitches memory, up to 10,000 patterns storage.

◆ 360 degree random quilting to make more vivid patterns for different markets.

◆ High end luxury mattresses; wedding products; children mattresses; different age requirements.

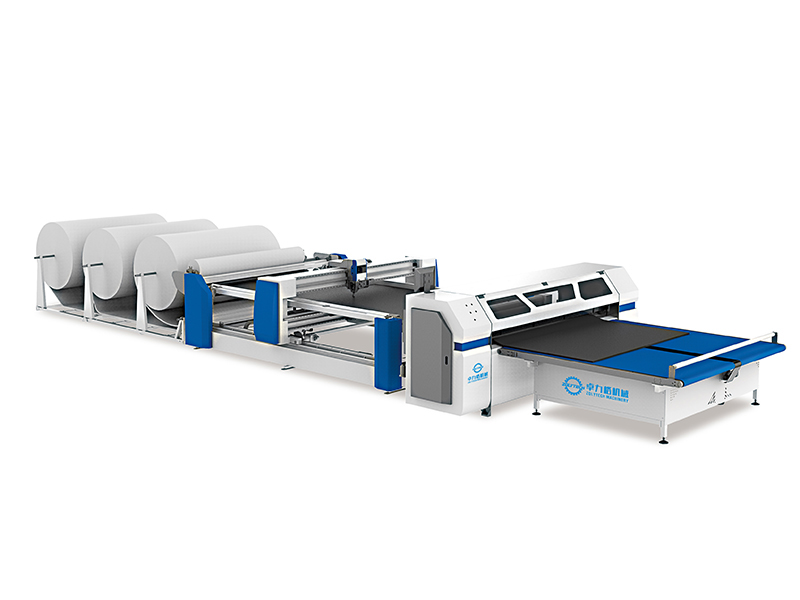

| Max quilting width | ≤2400 mm |

| Max rotating speed of needle | 2200 rpm |

| Max quilting thickness | ≤80 mm |

| Capacity | 40-120 m/h |

| Stitch length | 2-6 mm |

| Needle model | 19#, 21# |

| Gross weight | 3200 KG |

| Total power | 11 KW |

| Voltage | 380V/50Hz 220V/60Hz, 3-Phase |

| Dimension (L×W×H) | 10500×4530×2050 mm |

Maintenance tips from experienced engineers

◆ The average life of machine will be 1-2 years longer under good maintainance.

| 1 | Every day before off work | Clean dust of the flanging head and cutting box by gas gun | |

| 2 | While changing rotary shuttle | Adding oil on the shuttle bed | |

| 3 | 1 month | Check sewing head lubrication system or watch the oil window and add oil on time | |

| 4 | 1 month or according to the output | Add butter oil for every bearing of the machine | |