cameron.luo@zolytechmachinery.com

+86-18688657355

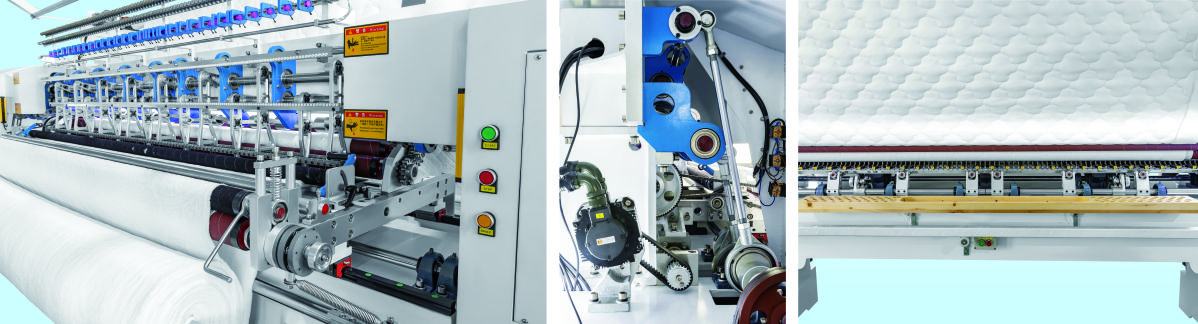

◆ New designed transmission structure and driven shaft assures the machine working stably with high speed ; More reasonable designed eccentricity of the arm force keeps the machine low noise in running state.

◆ Panasonic servo drive system.

◆ Needle bar and press plate are connected by cam-free double-swinging device, which is with high precision and durable. This structure can avoid lubrication and dirty material effectively.

◆ Both serial patterns and Tack & Jump patterns (360° and 180°) are available.

◆ The machine can stop automatically when the up thread breaks.

◆ Computerized automatic needle-lifting and speed adjustment.

◆ New generation of CNC system, advanced machine structure, high precision quilting, dispense with too much parameter adjustment or pattern modification during quilting.

◆ Precise CAD drawing.

◆ Fault detecting system.

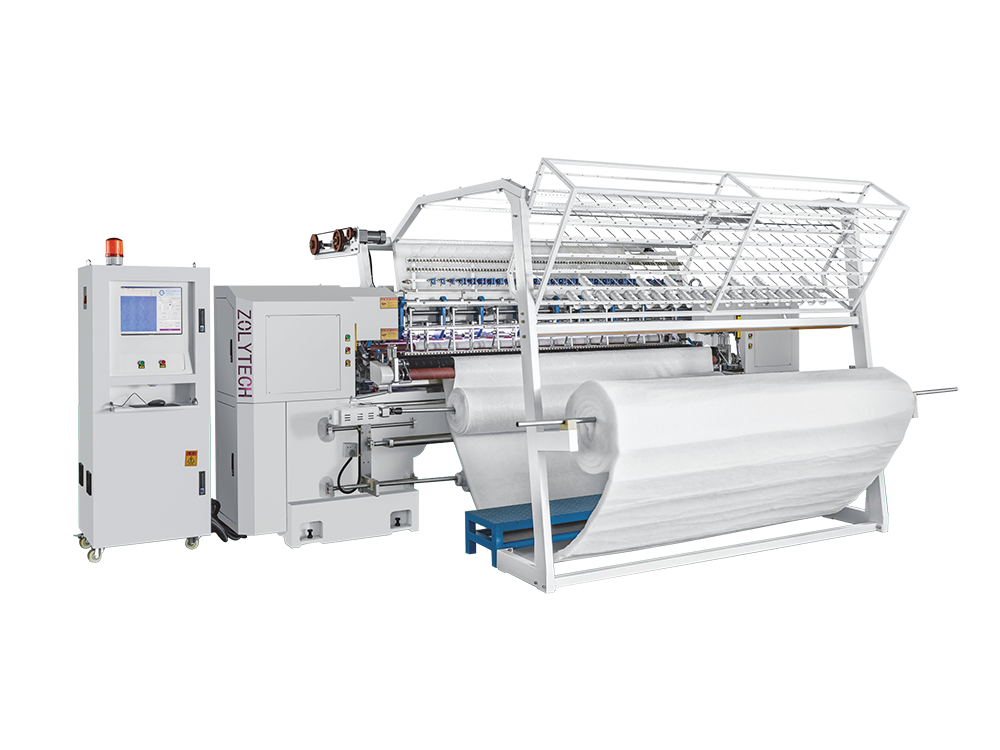

| Dimension (L×W×H) | 4800×1370×1780 mm |

| Quantity of needle bar | 3 |

| Quilting width | 2450mm |

| Space between needle bars | 76.2, 152.4 mm |

| Space between needles | 25.4mm |

| X-axis movement displacement | 304.8 mm |

| Thickness of quilting | ≤30 mm |

| Stitch length | 2-7 mm |

| Speed of production | 60-120 m/h |

| Model of needle | 16#, 19# |

| Speed of main shaft | 300-1000 rpm |

| Total power required | 4.5 KW |

| Voltage | 380V/50Hz 220V/60Hz, 3-Phase |

| Gross weight | 4000 KG |